The impact of xylan on the biosynthesis and structure of extracellular lignin produced by a Norway spruce tissue culture. Sapouna I, Kärkönen A, McKee LS. Plant Direct 7 (2023) e500.

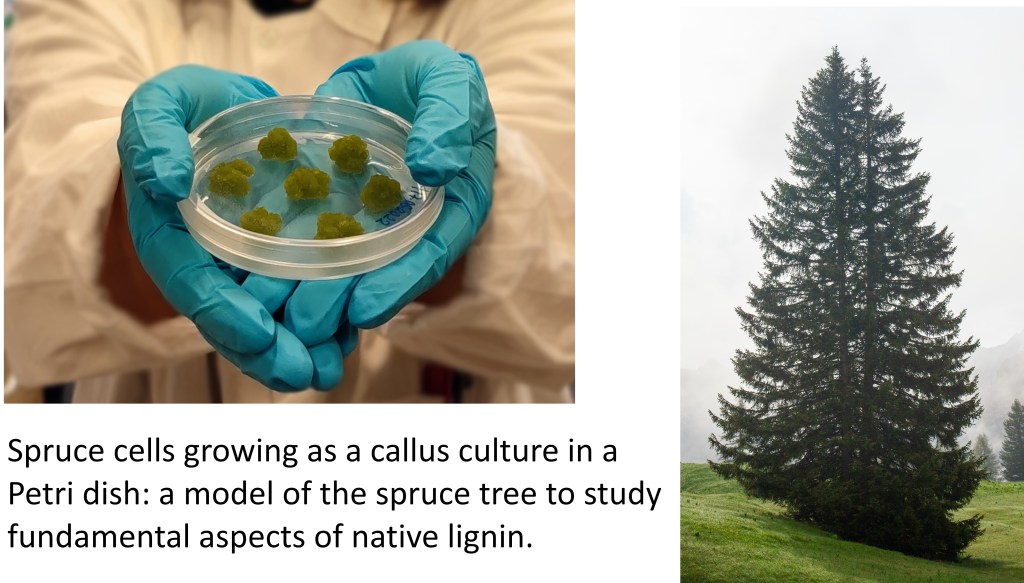

What does a spruce tree growing in a forest have in common with a few spruce cells growing in a Petri dish at KTH? At first sight, the differences are striking as the two systems seem to only share the same colour. Biologically speaking the two systems are indeed different, even though they share the same genome. For example, in the woody tissue, the lignin building blocks or monolignols, enter into the secondary plant cell wall, an environment of cellulose and non-cellulosic polysaccharides known as hemicelluloses, in which they form the lignin polymer.

By contrast, in the callus culture, the cells do not form a secondary cell wall and they do not produce monolignols. It is however possible to induce monolignol production by transferring the spruce cells from the agar plates they grow on into cultivation flasks with liquid medium. In this changed environment, the cells do secrete monolignols into the liquid medium, and these polymerize to lignin extracellularly. The key advantage of this model callus culture system is that lignin polymerizes outside of the cells, which means that we can collect it by a simple filtration step. Normally, in order to isolate lignin from woody tissue, extensive mechanical pre-treatments and extraction steps are required and these are known to alter the structure of native lignin and destroy the architecture of the plant cell wall. However, understanding the real chemical and physical interactions between lignin and its polymerization environment is an important step towards utilization of lignin, which until now is a major waste of the pulp and paper industry.

In our recently published study in Plant Direct we used the Norway spruce callus culture to understand the structure of native lignin and its interactions with a component of its natural polymerization environment, a hemicellulose named xylan (Sapouna et al., Plant Direct, 2023, 7, e500, doi.org/10.1002/pld3.500). Although similar studies have been performed on purely chemical systems, in which monolignols are introduced in a solution that contains an enzyme and the hemicellulose, the final structure of synthetic lignin is not very similar to the native one. We used several cultivation treatments in which xylan was added in different concentrations in the cells’ solid growth medium and/or in the monolignol polymerization liquid medium, and we found that the cells do indeed react differently in the presence of xylan. Even though there was no change in the morphology of the cells, i.e. the cells did not start forming a secondary cell wall, there was an increase in extracellular lignin production and the activity of an enzyme necesary for lignin polymerization, in the treatments with added xylan. Also, there were small changes in the structure of lignin in these treatments, which I studied by extensive NMR to understand the bond composition and SEC to determine the molecular weight.

This project, which started in 2019, was quite outside of my “being a chemist” comfort zone. In the beginning it was challenging to even learn how to keep the cells alive. Three years later, I was able to handle many samples at the same time and subculture about 80 plates in one day, every three weeks. Challenging projects are great opportunities to expand one’s knowledge and skills. As a chemist, I look at a reaction or synthesis and focus on the chemical properties of the reagents to understand the system and improve it, but there are many more variables in experiments that work with living tissue. Working on this project made me look at lignin from a different perspective. I came closer to understanding its biosynthesis and realized how sensitive and versatile the process can be. To decipher the structure of native lignin and its interactions with the other cell wall components, it is necessary to understand how lignin is produced and the simple parameters that can affect this process. It is when we fill in the existing knowledge gaps about the fundamental properties of lignin that we will be able to utilise it to its full potential, as a major product of the wood biomass.

Pingback: Year in review – 2023 | Stockholm CAZyme Lab